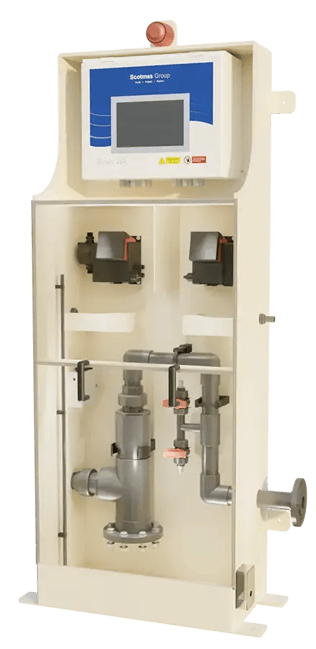

Bravo WA

Chlorine Dioxide Dosing and Control System

Stop Legionella, keep compliance and forget the chemical headaches.

Our Bravo WA unit produces chlorine dioxide (ClO₂) right inside your pipework, wiping out Legionella, E. coli and other water-borne pathogens without forming bromates, trihalomethanes (THMs) or other harmful by-products that plague traditional chlorination. That means healthier water for guests, patients, tenants and staff plus lower risk for you. The system can treat a flow of up to 160,000 l/hr water @0.5 mg/l ClO₂.

Fits every application

-

Hospitals & care homes – safeguard vulnerable people from Legionella and Pseudomonas.

-

Universities & hotels – maintain vast, complex pipework without end-point dosing.

-

Industrial parks & food factories – integrate with existing SCADA and CIP rigs.

-

Commercial tower blocks – one generator, many risers; stable residual right to the tap.

Expert Consultation and Guidance from Scotmas

With years of experience using ClO₂ in various challenging environments, Scotmas is well-equipped to tackle complex issues in water supplies. We can provide world-class expertise and guidance on all aspects of water disinfection, including regulatory compliance and environmental stewardship.

How it works

Meter-driven precision – Bravo WA links to a water meter and doses exactly in proportion to flow, so you always hit your set-point and never overdose.

In-line reactor magic – Two precursor chemicals meet in our water-jacketed reaction chamber. They instantly form ClO₂ inside the main line, already dissolved, ready to disinfect.

Real-time verification – Downstream Sentinel Guard analysers track ClO₂ residuals and chlorite automatically, feeding live data to your dashboard and alarms. The system can integrate with BMS/SCADA systems via Modbus IP link.

Smart shut-offs & alerts – Built-in inputs let you pause dosing from a timer, process signal or batch controller; e-mail/SMS alerts flag low reagents or out-of-spec residuals before there’s a problem.

Ready to simplify water safety?

Fill out the form for more info.

Why facilities teams choose the Bravo WA

| Benefit | What it means for you |

|---|---|

| Zero hazardous storage | Patented in-line reactor creates ClO₂ at the moment of injection - no pressurised gas cylinders, no bulk “free” ClO₂ drums, no leaks. |

| Legionella & pathogen control | Continuous dosing keeps systems biofilm-free. |

| No dangerous by-products | Eliminates THMs, bromates and chloramines - safer for occupants, simpler for compliance. |

| Plug-and-play monitoring | Industrial Panel PC plus remote “Insite” dashboard, full data logging, Modbus-IP & LoRa links for BMS/SCADA. |

| Standards compliant | Manufactured to EN 12671:2009 for total peace of mind. |

| Install anywhere | Wall-mounted skid, GRP outdoor kiosk or custom enclosure whatever suits your plant room. |

24/7 Protection

Advanced Chlorine Dioxide dosing systems provide continuous disinfection against Legionella and Pseudomonas in healthcare and workplace environments.

Bespoke Solutions

Scotmas experts work with your existing Water Safety Plan and Risk Assessment, ensuring compliance with regulations like HTM04-01.

No Hazardous Storage

On-demand generation of Chlorine Dioxide in the plant room eliminates the need to store unstable or hazardous chemical solutions.

Real-Time Monitoring

Integrated monitoring devices track system performance, with secure web portal access to up to 3 years of compliance records.

Regulatory Compliance

Our solutions are regulator-approved for continuous use in drinking water supplies and designed to protect vulnerable populations.

Proven Trust

Over 20,000 patients benefit from Scotmas systems installed across NHS and private healthcare settings nationwide.

Scotmas is registered with the Legionella Control Association.

You can view our certificate of registration by clicking here.